Modules

Planned & Predictive Maintenance

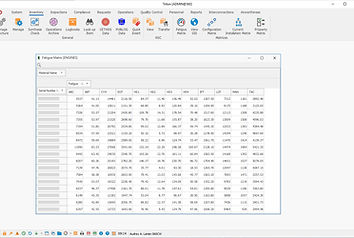

TRITON EAM assists with all planned, preventive & predictive maintenance procedures of your assets. It enables business alignment with all existing and future maintenance rules, and monitors embedded attributes of material databases in accordance with the Original Equipment Manufacturer (OEM) directives and performance criteria.

CAPABILITIES

-

Scheduled maintenance planning & control

-

Predictive maintenance forecasting

-

Maintenance cycle execution & reporting

-

Comparative maintenance load statistical analysis

-

Inspection scheduling & management

Industries

Explore how TRITON EAM revolutionizes asset management in your industry, and save by switching your legacy EAM system.

Critical Asset Management, Secured

TRITON ensures mission-critical asset readiness with secure, on-premises infrastructure, minimizing downtime for defense systems across land, sea, air and space.

Fleet Uptime, Maximized

TRITON streamlines aviation maintenance with real-tme diagnostics, predictive MRO scheduling and optimization, ensuring highler fleet availability and FAA/EASA compliance for airlines and MRO providers.

Production Efficiency, Supercharged

TRITON enhances manufacturing with Industry 4.0 integration, predictive maintenance and digital twins, reducing production downtime and optimizing resource use for smarter, faster operations.

Reliability, Powered-up

TRITON drives the energy sector with 360-degree asset monitoring and predictive failure analysis ensuring uninterrupted operations across the whole value chain, from downstream to upstream.